Industrial Gases for Welding: Why Oxygen, Acetylene, and Argon Matter

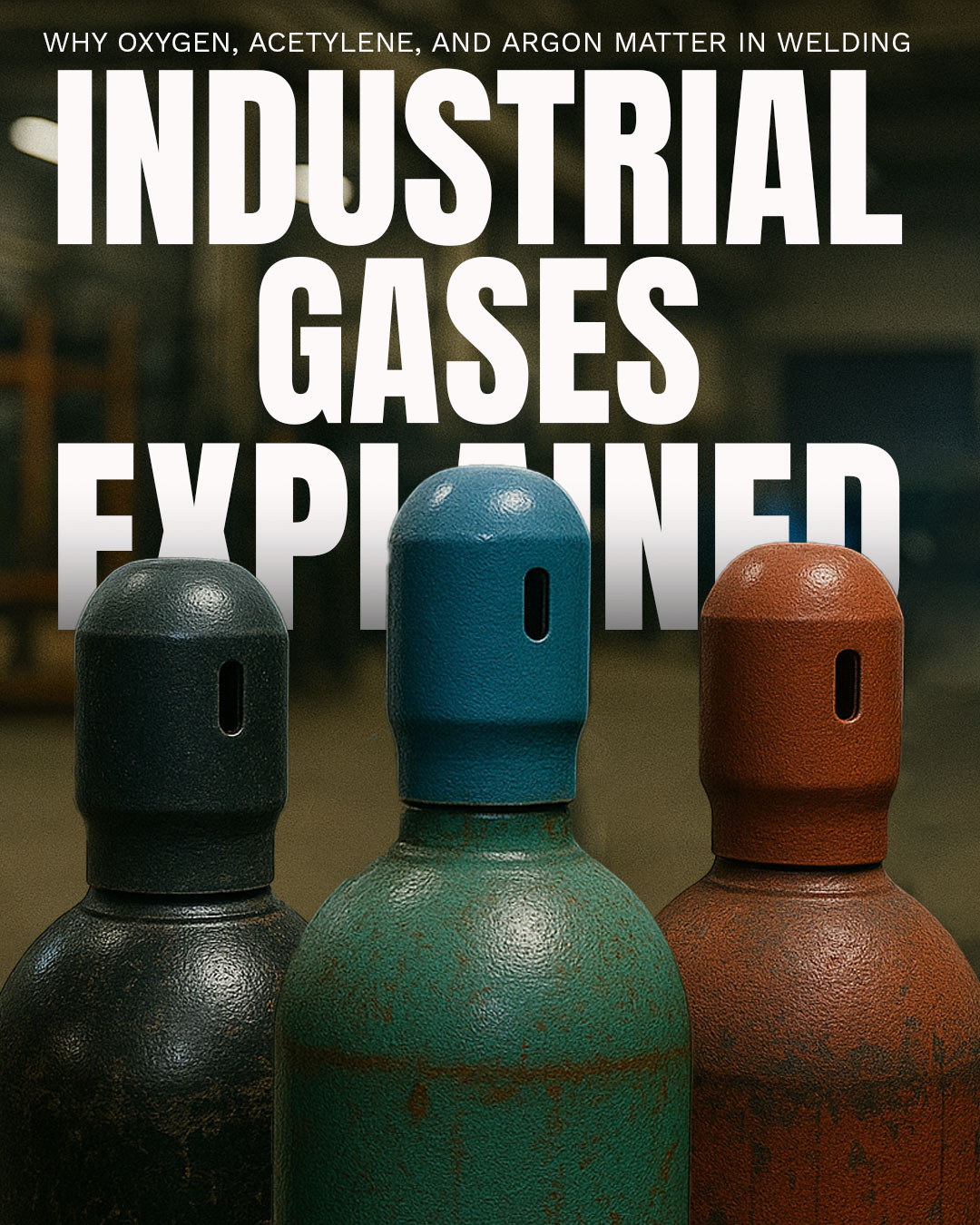

When most people think about welding, they picture sparks flying and the hum of a powerful machine. But there’s a silent force at work that can make or break the quality of your weld: industrial gases for welding. Oxygen, acetylene, and argon might not get the spotlight, but they shape the flame, shield your work, and help you achieve strong, clean, precise results.

Oxygen in Welding

Role: Supports combustion and increases flame temperature when combined with fuel gases.

- Benefits: Creates a hotter flame for faster, cleaner cutting; improves efficiency in oxy-fuel welding and cutting.

- Applications: Oxy-acetylene welding, cutting torches, heating applications in fabrication.

- Safety Tip: Store cylinders upright, secured with a chain or strap. Keep oxygen away from oil, grease, or other flammable materials — contamination can cause dangerous reactions.

Oxygen is one of the most widely used industrial gases for welding because it supports combustion and helps achieve clean, precise cuts.

Acetylene in Welding

Role: Primary fuel gas for oxy-fuel welding and cutting.

- Benefits: Produces the hottest flame of any common fuel gas (up to ~5,700°F); cuts quickly and precisely through thick steel.

- Applications: Flame cutting, brazing, heating and bending metal.

- Safety Tip: Never use acetylene at pressures above 15 psi; always store and transport cylinders upright in well-ventilated areas.

Among common industrial gases for welding, acetylene delivers exceptional flame temperatures for cutting and brazing.

Argon in Welding

Role: Inert shielding gas that protects the weld area from atmospheric contamination.

- Benefits: Provides a stable arc and cleaner welds; reduces spatter and oxidation; works well with many metals, especially non-ferrous ones.

- Applications: TIG welding aluminum and stainless steel; MIG welding non-ferrous metals like aluminum, copper, and magnesium.

- Safety Tip: Argon is non-toxic, but it can displace oxygen in enclosed spaces — always work in a well-ventilated area.

As a key part of industrial gases for welding operations, argon enables smooth, clean TIG and MIG welds on aluminum and stainless steel.

Choosing the Right Industrial Gases for Welding

| Gas |

Role in Welding |

Best For |

| Oxygen |

Combustion support |

Oxy-acetylene welding, cutting |

| Acetylene |

Fuel gas |

Cutting, brazing, some welding |

| Argon |

Shielding gas |

TIG & MIG welding aluminum, stainless steel |

Safety First

- Use the Right PPE: Flame-resistant clothing, safety glasses or welding goggles, gloves.

- Store Correctly: Keep cylinders upright, secure them with chains or straps, and use safety caps when not in use.

- Know Your Codes: Follow OSHA and local safety regulations for storage, transport, and usage.

Why Buy from Phoenix Welding Supply?

- Top-Quality Gas Supply: Consistent, reliable purity and pressure.

- Expert Guidance: Our team can recommend the best gas for your application.

- Local Convenience: Six Arizona locations — Phoenix, Mesa, Deer Valley, Flagstaff, Sierra Vista, and Tucson.

Final Word

The right gas can transform your welding — making the difference between a rough, messy weld and a clean, strong joint. Whether you’re cutting steel with oxy-acetylene or laying down a perfect TIG bead on aluminum, understanding industrial gases for welding is key to success.

Ready to get started? Visit your nearest Phoenix Welding Supply location today or give us a call for expert advice on industrial gases, welding equipment, and more.