Municipal aquatics facilities face ongoing challenges with water chemistry control, rising chemical costs, and operator safety. The Town of Queen Creek Aquatics and Recreation Department partnered with Phoenix Welding Supply to implement a CO2 injection system designed to improve pH control while significantly reducing chemical usage and operating costs.

The Town of Queen Creek operates public aquatics facilities that serve the community year round. The facilities prioritize swimmer safety, consistent water quality, and efficient operations. Managing pH levels had traditionally required large volumes of muriatic acid and sodium bicarbonate, particularly during peak usage months.

Before installing a CO2 system, Queen Creek relied heavily on traditional chemical dosing to maintain proper pH and alkalinity. This resulted in:

High daily consumption of acid and sodium bicarbonate

Fluctuating pH levels that required frequent adjustments

Rising operational and chemical costs

Increased handling of corrosive chemicals by staff

The department sought a more stable and cost effective solution that would also improve workplace safety.

Phoenix Welding Supply installed a CO2 system in June. CO2 lowers pH by forming carbonic acid when dissolved in pool water while naturally increasing alkalinity through bicarbonate ions. This approach creates smoother pH control and reduces the need for corrective chemical dosing.

Phoenix Welding Supply provided system installation, CO2 supply, and ongoing support to ensure the system was properly tuned for optimal performance.

The Results |

|

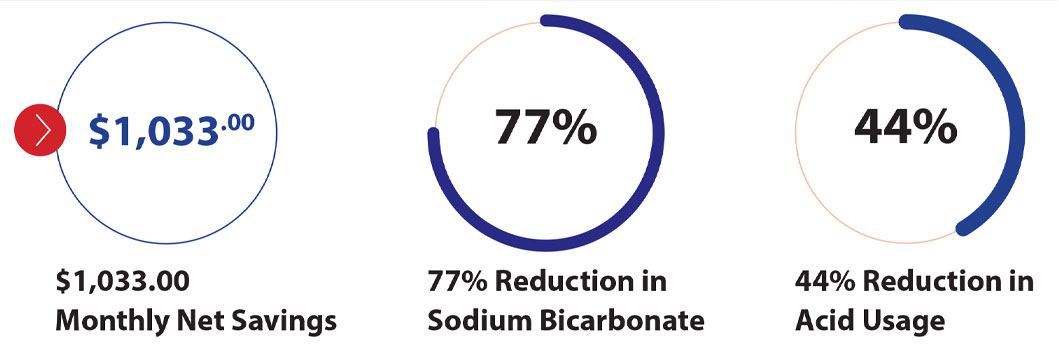

Following installation, Queen Creek recorded measurable improvements in chemical usage, water stability, and operating costs. |

Chemical Usage Reduction |

||||

| Category | Before CO2 | After CO2 | Reduction | Decrease |

|---|---|---|---|---|

| Sodium Bicarbonate | 68.55 pounds per day | 15.53 pounds per day | 53.02 pounds per day | 77 percent |

| Acid Usage | 7.59 gallons per day | 4.25 gallons per day | 3.34 gallons per day | 44 percent |

These results were achieved during peak season, with additional savings expected year round as the system continues to operate.

Dwayne Lang, Facility Services Supervisor for Aquatics and Recreation, Town of Queen Creek, shared:

“We are very happy with the cost savings we are seeing after installing the CO₂ system from Phoenix Welding Supply. The reduction in chemical usage has been significant, and the system has helped us maintain more stable water conditions. If you ever need a reference for a potential customer, I am more than happy to help and can even provide a tour of our chemical feed system.”

Phoenix Welding Supply delivers proven CO2 solutions for aquatics, water treatment, and industrial applications across Arizona. Customers rely on Phoenix Welding Supply for:

Reliable CO2 supply and delivery

Expert system installation and support

Cost effective solutions with measurable ROI

Long term partnership and local service

The Queen Creek Aquatics CO2 system installation demonstrates how facilities can improve water chemistry, reduce chemical costs, and enhance operational efficiency with the right solution and support. Phoenix Welding Supply continues to help municipalities and private facilities achieve safer, more efficient, and more sustainable operations.