Choosing the right welding equipment is one of the most important decisions any welder can make — whether you’re just starting out or upgrading your shop. This comprehensive guide covers the essentials of MIG, TIG, and Stick welding, helping you match the right machine to your materials, power supply, budget, and long-term goals. By the end, you’ll have the knowledge and confidence to select equipment that improves your efficiency, weld quality, and safety on every project.

Ever stood in front of a wall of welding machines and felt like they were speaking another language? You’re not alone. With so many brands, processes, and specifications to consider, picking the wrong machine can cost you time, money, and frustration.

Whether you’re a hobbyist tackling your first project or a seasoned pro looking to upgrade, the right equipment will save you headaches and deliver better results. Let’s break down the process step-by-step so you can find your perfect welding match.

Before you start shopping, take a close look at your project requirements.

Type of Metal – Some welders handle aluminum better than others, while mild steel and stainless steel have their own needs.

Material Thickness – Thicker metal requires more power (amperage).

Work Environment – Are you welding in a shop or outdoors in the elements? Portability matters.

Quick Metal-to-Process Guide:

| Metal | Best Welding Type | Notes |

|---|---|---|

| Mild Steel | MIG, Stick | Easy to weld, forgiving for beginners |

| Stainless Steel | TIG | Produces clean, precise welds |

| Aluminum | TIG, MIG (with spool gun) | Requires special handling |

Best for: Beginners, high-speed projects, mild steel

Pros: Easy to learn, fast, versatile

Cons: Not ideal for outdoor windy conditions

Best for: Precision work, aluminum, stainless steel

Pros: Extremely clean welds, works on many metals

Cons: Slower, requires more skill and coordination

Best for: Outdoor work, repair jobs, rusty or dirty metal

Pros: Forgiving on less-than-perfect surfaces, inexpensive

Cons: Less precise, more spatter to clean up

Before you fall in love with a machine, check your available power:

120V: Standard household outlets—fine for lighter jobs

240V: Industrial shops or heavy-duty projects

Dual Voltage: Flexibility to work in multiple environments

💡 Tip: Always ensure your circuit can handle the welder’s amperage draw.

Portability: If you’ll be moving the machine often, look for lighter models with sturdy handles or carts.

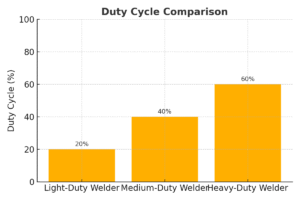

Duty Cycle: Indicates how long the welder can operate before it needs to cool down. A higher duty cycle = more continuous welding time.

Think beyond your first project:

Buy for growth – Invest in a machine that can handle future, more advanced projects.

Don’t forget accessories – Helmets, gloves, regulators, gas cylinders, and consumables should be part of your budget.

No matter which machine you choose:

Wear appropriate PPE—auto-darkening helmet, flame-resistant clothing, gloves.

Work in a well-ventilated area.

Learn proper safety procedures before striking your first arc.

When you purchase from Phoenix Welding Supply, you get more than a machine:

Expert Advice – Our team knows welding inside and out and can match you with the perfect equipment.

Top Brands – We carry only trusted, high-performance equipment.

Local Service – Six Arizona locations: Phoenix, Mesa, Deer Valley, Flagstaff, Sierra Vista, and Tucson.

The right welder is the one that fits your project needs, your skill level, and your long-term goals. Whether you’re after precision TIG work or all-purpose MIG versatility, making an informed choice will set you up for welding success.

Ready to find your perfect welder?

Stop by your nearest Phoenix Welding Supply location or give us a call today—our experts are ready to help you get started.