Choosing between TIG and MIG comes down to the material, finish quality, and speed you need. This quick guide explains the core differences, what gases each process uses, and how to pick the right setup for your project or shop.

MIG uses a continuously fed wire and a shielding gas to protect the weld pool. It is fast, easy to learn, and great for production or frequent tack welds. Many shops use argon and CO2 mixtures for mild steel, while straight argon is common for aluminum when paired with the right wire and spool gun.

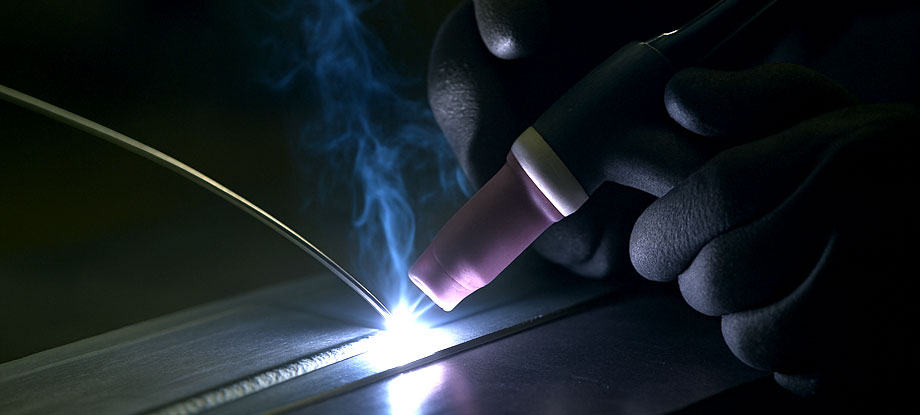

TIG uses a non-consumable tungsten electrode with a separate filler rod. The shielding gas is typically argon. TIG offers precise heat control and a clean, cosmetic finish on stainless, aluminum, and thin materials. It takes more practice than MIG but rewards you with tight, professional results.